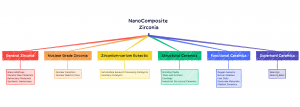

Introduction

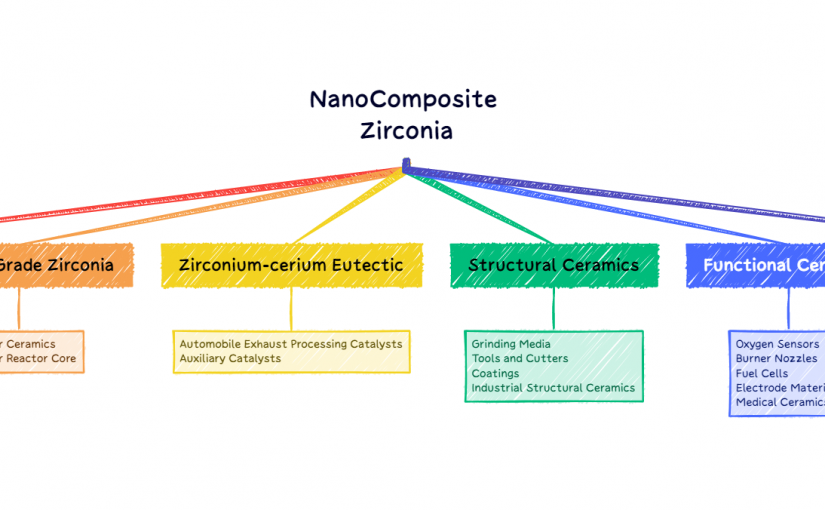

Nano Composite Zirconia is a versatile and advanced ceramic material that has found extensive applications across various industries. This material is celebrated for its excellent mechanical properties, thermal stability, and resistance to wear and corrosion. This article introduces the various categories and applications of Nano Composite Zirconia.

1. General Zirconia

General Zirconia serves as a fundamental building block for various advanced applications. Key uses include:

- Glass Additives: Enhances the mechanical strength and thermal stability of glass products.

- Ceramic Raw Materials: Provides a robust foundation for manufacturing high-performance ceramic products.

- Refractory Materials: Offers exceptional resistance to high temperatures, making it ideal for furnace linings and other high-heat environments.

- Synthetic Gemstones: Used in the creation of aesthetically pleasing and durable synthetic gemstones.

2. Nuclear Grade Zirconia

Nuclear Grade Zirconia is specifically engineered for use in nuclear applications due to its exceptional stability and resistance to radiation:

- Nuclear Ceramics: Utilized in the fabrication of ceramic components that are essential in nuclear reactors.

- Nuclear Reactor Core: Plays a crucial role in maintaining the integrity and safety of the reactor core.

3. Zirconium-Cerium Eutectic

This category focuses on the combination of Zirconium and Cerium to produce materials with enhanced catalytic properties:

- Automobile Exhaust Processing Catalysts: Used to convert harmful emissions into less toxic substances.

- Auxiliary Catalysts: Enhances the efficiency and performance of various catalytic processes.

4. Structural Ceramics

Structural Ceramics made from Nano Composite Zirconia are known for their outstanding mechanical properties and durability:

- Grinding Media: Provides excellent wear resistance, ensuring longevity in milling processes.

- Tools and Cutters: Used in the manufacturing of cutting tools due to their hardness and durability.

- Coatings: Applied as protective coatings to enhance the lifespan of components exposed to harsh environments.

- Industrial Structural Ceramics: Used in various structural applications in industries due to its strength and resilience.

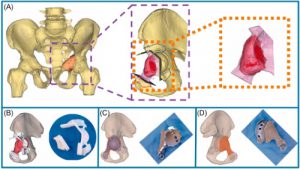

5. Functional Ceramics

Functional Ceramics from Nano Composite Zirconia are designed for specific, high-performance applications:

- Oxygen Sensors: Crucial in monitoring and regulating oxygen levels in various industrial processes.

- Burner Nozzles: Ensures efficient and controlled combustion in burners.

- Fuel Cells: Used in the development of efficient and durable fuel cell components.

- Electrode Materials: Provides superior conductivity and stability in various electrochemical applications.

- Medical Ceramics: Widely used in medical implants and devices due to its biocompatibility and durability.

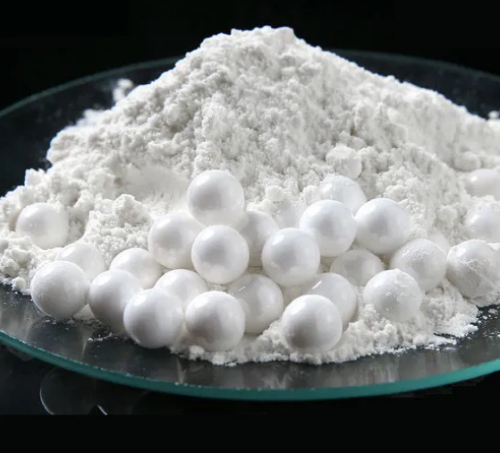

6. Superhard Ceramics

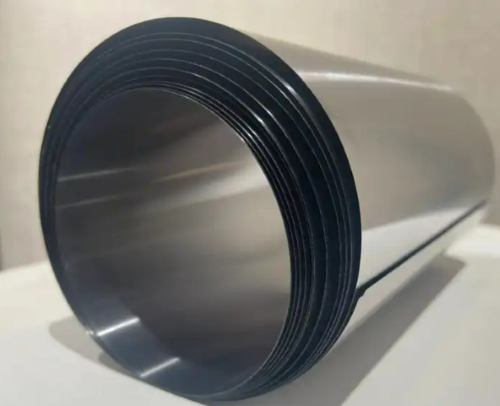

Superhard Ceramics are engineered to withstand extreme conditions and mechanical stress:

- Bearings: Offers high wear resistance and durability, essential for bearings in high-stress environments.

- Bearing Balls: Used in various mechanical applications where superior hardness and longevity are required.

Conclusion

Nano Composite Zirconia stands out as a multifaceted material with a broad range of applications. From general industrial uses to specialized nuclear and catalytic applications, this advanced ceramic material continues to play a pivotal role in modern technology and industry. Its exceptional properties make it a material of choice for applications requiring high performance, durability, and stability. For more detailed information related to zirconium products, companies like Advanced Refractory Metals (ARM) provide extensive resources and expertise.