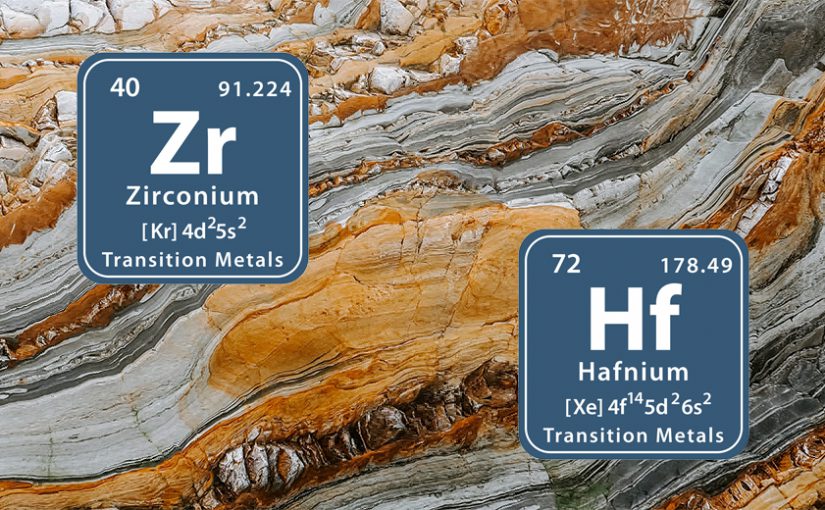

Zircon sand, also known as zircon, is a mineral mainly composed of zirconium silicate (Zr2SiO4). Pure zircon is colorless and transparent crystal; depending on the origin, type, and quantity of impurities, zircon sand may appear in yellow, orange, red, brown, and other colors. The uniform Mohs hardness of zircon is 7-8, the refractive index is 1.93-2.01, and the melting point fluctuates within 2190-2420 ℃ with different impurities.

Chemical Composition

The main chemical composition of zircon is ZrO2 & SiO2, and a small amount of impurities such as Fe2O3, CaO, AI2O3, etc. The theoretical composition of zircon sand is ZrO2: 67.1%; SiO2: 32.9%. It is the only compound in the ZrO2-SiO2 system. But natural zircon sand only contains about 57~66% ZrO2.

Properties

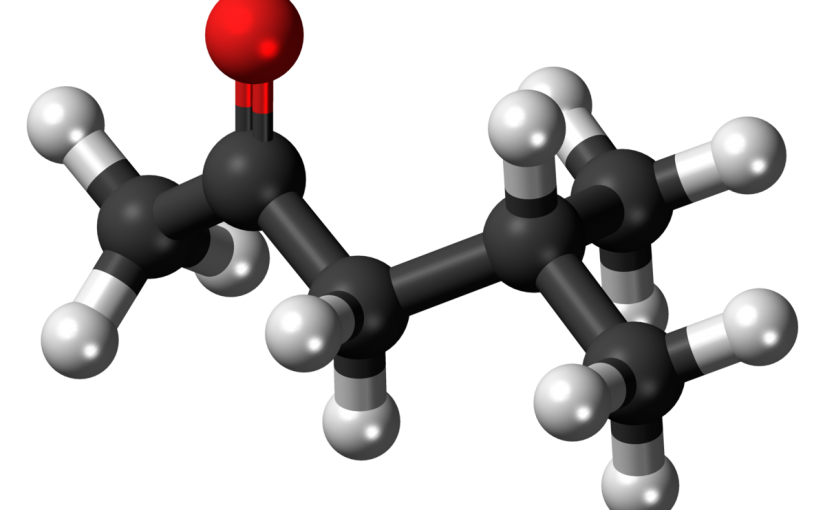

Zircon is a mineral composed primarily of zirconium, silicon, and oxygen that crystallized out of magma when igneous rocks formed. It is the most important zirconium-bearing mineral – it is the most widely distributed, the most abundant, and the most types of zirconium minerals. Zircon belongs to the tetragonal crystal system, often in the form of well-developed cone-shaped small square cylinders, and also irregular granular. It is brittle and has a shell-like fracture. It is mostly symbiotic with ilmenite, rutile, monazite, xenotime, etc. in the coastal sand.

Application

Zircon is the main raw material for the preparation of zirconium, hafnium and various zirconium products. It is also a high-quality refractory material with high melting point, low thermal conductivity and small linear expansion coefficient, and is widely used in metallurgy, casting and other industries.

The addition of zircon to other materials can improve their performance. For example, adding zircon sand to synthetic cordierite can broaden the sintering range of cordierite without affecting its thermal shock stability; Adding zircon sand to high-alumina bricks to manufacture anti-stripping high-alumina bricks, the thermal shock stability is greatly improved; It can also be used to extract ZrO2.

More specific applications are as follows:

Refractory: zirconium refractory, such as zirconium corundum brick, zirconium refractory fiber;

Sand for casting mold in the foundry industry: molding sand for precision casting, precision enamel utensils;

Glass, metal: sponge zirconium;

Production of zirconium compounds: such as zirconium dioxide, zirconium oxychloride, sodium zirconate, potassium fluorozirconate, zirconium sulfate, etc.

If you are interested in other zirconium materials, please visit https://www.samaterials.com/.