Introduction

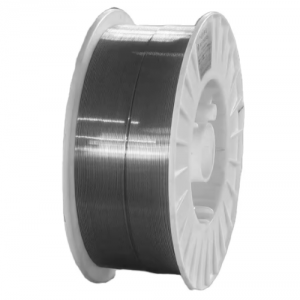

Zirconium (Zr) is a remarkable metal known for its exceptional properties, making it a valuable material in various advanced technological applications. Among its many forms, zirconium wire stands out for its versatility and efficacy in specialized processes such as plasma cutting and evaporation coating. This article discusses the unique characteristics of zirconium wire and its significant roles in these cutting-edge applications.

Properties of Zirconium

Before exploring its applications, it is essential to understand the properties that make zirconium an excellent choice for high-performance applications.

- Zirconium boasts a high melting point of 1855°C, making it extremely resistant to heat.

- Additionally, it has excellent corrosion resistance, particularly against alkalis, acids, and seawater, which ensures its durability and longevity in harsh environments.

- Zirconium is also known for its strength and ductility, which allow it to be easily shaped into various forms, including wire, without compromising its structural integrity.

Related reading: 8 Interesting Facts About Zirconium

Zirconium Wire in Plasma Cutting

Plasma cutting is a process that employs a high-velocity jet of ionized gas, or plasma, to cut through conductive materials. This method is renowned for its precision and speed, making it ideal for applications requiring detailed and rapid cuts.

Zirconium wire is highly suitable for plasma cutting due to its ability to withstand the extreme temperatures generated during the process. The wire’s high melting point ensures that it remains stable and effective, even under intense thermal conditions.

In addition to its heat resistance, zirconium’s corrosion-resistant properties ensure that the wire remains effective over prolonged use, even when exposed to potentially corrosive environments. This longevity is particularly beneficial in industrial settings where maintaining consistent performance is critical.

Related reading: Electrode Materials for Plasma Cutting Machines

Zirconium Wire in Evaporation Coating

Evaporation coating is another area where zirconium wire excels. This process involves heating the wire in a vacuum chamber until it evaporates, creating a thin film of material that coats a substrate.

Zirconium’s high melting point and excellent evaporation characteristics make it an ideal source material for this application. The resultant coatings are uniform and adherent, providing superior surface properties to the coated substrates.

Evaporation coating with zirconium wire is widely used in several industries.

- In the optics industry, zirconium coatings are applied to lenses and mirrors to enhance their reflective and protective properties.

- In the semiconductor industry, zirconium coatings improve the performance and longevity of electronic components.

- Additionally, decorative coatings in various consumer products benefit from zirconium’s aesthetic appeal and durability.

Conclusion

Zirconium wire’s exceptional properties make it an invaluable material in advanced technological applications, particularly in plasma cutting and evaporation coating. Its high melting point, corrosion resistance, and strength ensure reliable performance and durability.

Whether in the form of coiled wire or particles, zirconium wire continues to enable innovations and improvements across various industries, highlighting its critical role in modern technology. As research and development in material science progress, the applications of zirconium wire are likely to expand further, unlocking new potentials and driving future advancements.

Advanced Refractory Metals (ARM) provides zirconium wires and related products at competitive prices and within a short time. Great delivery and nice customer service are also available on our website. For customized zirconium products, please check our homepage for more messages.