Introduction

Refractory metal crucibles are critical components in high-temperature industrial processes. These crucibles, made from metals with exceptionally high melting points, are designed to withstand extreme environments without losing their structural integrity. This article discusses the types of refractory metal crucibles, their characteristics, and their diverse applications.

What Are Refractory Metals?

Refractory metals are a group of metallic elements known for their exceptional resistance to heat and wear. The most common refractory metals include tungsten (W), molybdenum (Mo), tantalum (Ta), niobium (Nb), and rhenium (Re). These metals have melting points above 2000°C, with tungsten having the highest melting point of all elements at 3422°C.

- Refractory metals possess high melting points, maintaining strength and resisting deformation under extreme heat, ideal for high-temperature applications.

- They exhibit excellent thermal conductivity, ensuring uniform temperature distribution within the crucible, crucial for crystal growth and metal casting.

- These metals resist chemical attack, suitable for reactive or corrosive substances.

- Their mechanical strength remains intact at elevated temperatures, ensuring structural stability.

- Additionally, they have low vapor pressures at high temperatures, reducing contamination risks in sensitive processes like semiconductor manufacturing.

Types of Refractory Metal Crucibles

1. Tungsten Crucibles:

Tungsten crucibles are widely used in high-temperature applications due to their superior melting point and thermal conductivity. They are commonly employed in processes such as sapphire crystal growth, glass melting, and high-temperature alloy production.

2. Molybdenum Crucibles:

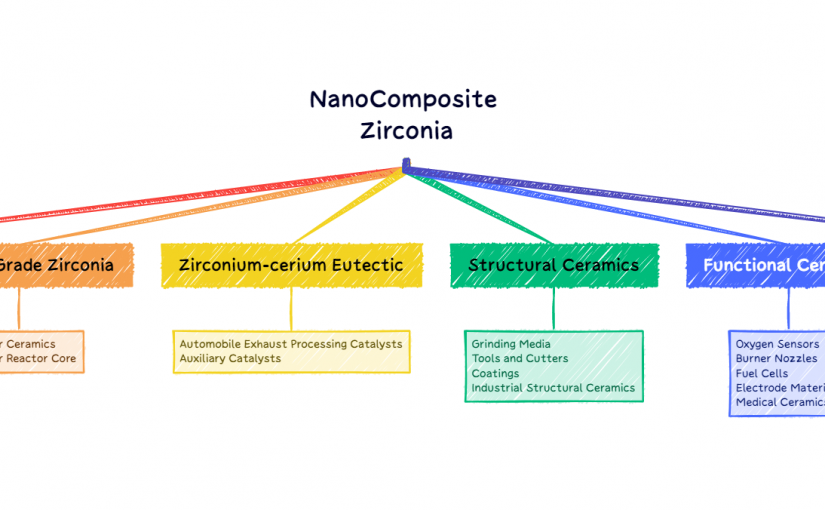

Molybdenum crucibles offer a good balance between a high melting point and machinability. They are often used in the production of molybdenum-based alloys, the glass industry, and for melting and holding reactive metals like titanium and zirconium.

3. Tantalum Crucibles:

Tantalum is known for its excellent corrosion resistance, making it suitable for applications involving highly reactive materials. Tantalum crucibles are used in the chemical processing industry, particularly for processes involving acids and other corrosive substances.

4. Niobium Crucibles:

Niobium crucibles are used in applications where both high temperature and chemical resistance are required. They are particularly useful in the production of high-purity crystals and in the electronics industry.

5. Rhenium Crucibles:

Rhenium is often used as an alloying element with other refractory metals to enhance their properties. Rhenium crucibles are utilized in applications that require extreme thermal stability and resistance to deformation, such as in rocket engine components and high-temperature furnace parts.

Applications of Refractory Metal Crucibles

- Aerospace and Defense: The aerospace industry relies on refractory metal crucibles for producing high-performance materials and components, including turbine blades and other parts exposed to extreme heat.

- Electronics and Semiconductors: In the electronics industry, refractory metal crucibles are used in manufacturing semiconductors, LEDs, and other high-purity materials that require contamination-free processing.

- Glass and Ceramics: Refractory metal crucibles play a crucial role in the glass and ceramics industry, where they are used for melting and holding molten glass and ceramics at high temperatures.

- Chemical Processing: The chemical industry uses these crucibles for processes involving highly reactive and corrosive chemicals. Tantalum crucibles, in particular, are favored for their resistance to acidic environments.

- Metal Processing: Refractory metal crucibles are essential in the metallurgical industry for melting and alloying metals that require high temperatures, such as titanium, zirconium, and superalloys.

Conclusion

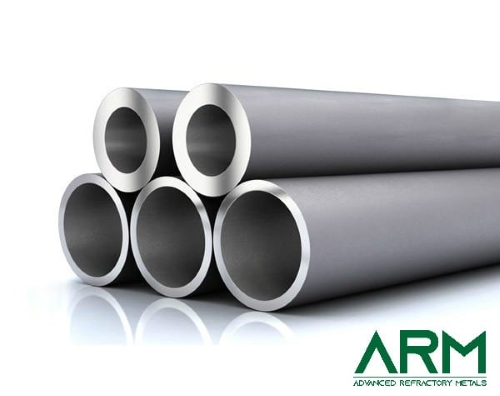

Refractory metal crucibles are indispensable in industries requiring high-temperature processing and handling reactive or corrosive materials. Their exceptional properties, including high melting points, thermal conductivity, and corrosion resistance, make them ideal for various demanding applications. As technology advances, the use of refractory metal crucibles is expected to expand, driven by the need for more efficient and durable materials in high-temperature environments. For more refractory metal products, please check Advanced Refractory Metals (ARM).