Introduction

Zirconium aluminum alloy stands out due to its exceptional properties and versatile applications across a range of industries. This alloy is a combination of zirconium and aluminum, and it is highly sought after for its strength, corrosion resistance, and suitability for high-temperature environments.

This guide delves deep into the characteristics, production, and uses of zirconium aluminum alloy, offering insights into why it is a preferred material in critical and high-performance applications.

Properties of Zirconium Aluminum Alloy

This alloy comes with unique properties.

- Enhanced Strength and Hardness: The addition of zirconium to aluminum significantly improves the alloy’s strength and hardness. This is due to the formation of zirconium aluminides within the matrix, which are hard and stable at high temperatures.

- Corrosion Resistance: Zirconium is highly resistant to corrosion, and when alloyed with aluminum, imparts this property to the mix. This makes the alloy resistant to a variety of chemical environments, including those encountered in marine and chemical processing applications.

- High-Temperature Stability: Unlike pure aluminum, which loses much of its strength at high temperatures, zirconium aluminum alloy retains much of its structural integrity even when exposed to elevated temperatures. This characteristic is crucial for applications in aerospace and automotive industries.

- Low Neutron Absorption: Zirconium’s low neutron-absorption cross-section makes the alloy beneficial for use in nuclear applications, where minimizing neutron absorption is critical.

- Good Thermal Conductivity: While the thermal conductivity of the alloy is generally lower than that of pure aluminum, it is still sufficient for many applications that require heat dissipation, such as in electronics and automotive components.

Related reading: Zirconium Alloys 101

Production Techniques

The production of zirconium aluminum alloy typically involves advanced metallurgical processes to ensure the even distribution of zirconium within the aluminum matrix and to achieve the desired mechanical properties:

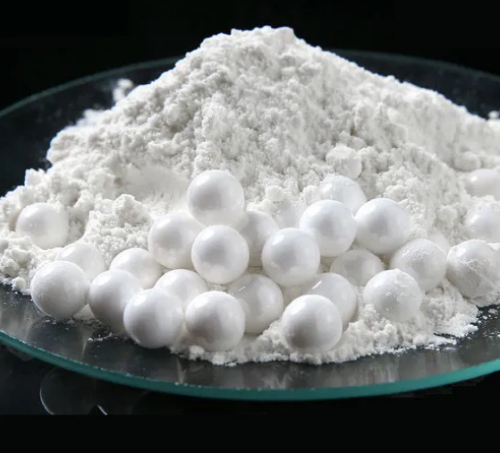

- Melting and Casting: The alloy is produced by melting the two metals together in a controlled environment to prevent oxidation and contamination. This mixture is then cast into molds to form ingots or billets.

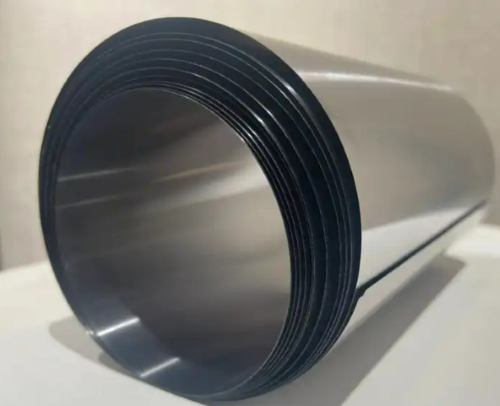

- Forging and Rolling: These ingots or billets can be further processed by forging or rolling, which refines the alloy’s grain structure and improves its mechanical properties.

- Heat Treatment: Heat treatment processes such as annealing or quenching and tempering are often applied to zirconium aluminum alloys to enhance their strength and hardness.

Applications of Zirconium Aluminum Alloy

- Aerospace: In aerospace, the alloy is used for parts that require high strength-to-weight ratios and good thermal stability, such as in aircraft frames, engine parts, and spacecraft components.

- Automotive: The automotive industry uses this alloy for components that need to withstand high temperatures and corrosive environments, including in engines and exhaust systems.

- Nuclear Industry: The low neutron absorption of zirconium makes this alloy ideal for nuclear applications, particularly in the fabrication of cladding for nuclear fuel rods.

- Sporting Equipment: The strength and lightweight characteristics of the alloy are advantageous for high-performance sporting equipment like bicycle frames and golf clubs.

- Marine and Chemical Processing: Its excellent corrosion resistance makes zirconium aluminum alloy suitable for marine hardware and equipment used in the harsh environments of chemical processing plants.

Future Outlook and Innovations

The ongoing research and development in the field of metal alloys are likely to further enhance the properties of zirconium aluminum alloys. Innovations in alloy composition and refinement of production techniques could lead to even higher performance materials. For instance, nanostructuring the alloy or adding other elements could provide better wear resistance, higher strength, or improved thermal properties.

Conclusion

Zirconium aluminum alloy is a remarkable material that combines the lightweight nature of aluminum with the strength and corrosion resistance of zirconium. Its diverse applications underscore its importance in modern technology and industry, where materials are often pushed to their limits.

As industries continue to demand materials that can perform under extreme conditions, zirconium aluminum alloy will likely remain a critical component in the design and manufacture of the next generation of technological advancements.

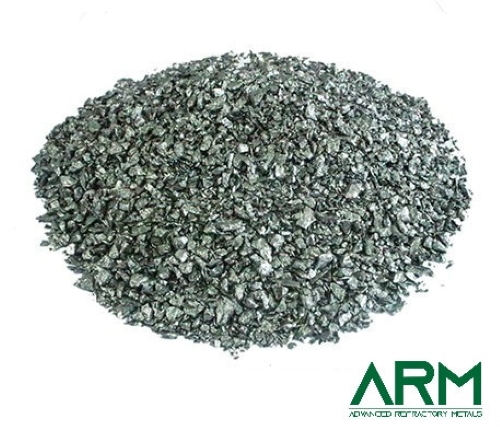

High-purity Zirconium Aluminum Alloy (ZrAl Alloy) is supplied by Advanced Refractory Metals (ARM). A range of zirconium products is also available. Send us an inquiry if you are interested.