Zirconium (Zr) is estimated to make up about 0.017% of the lithosphere. Because zirconium is chemically active at temperatures only slightly above normal atmospheric temperatures, it exists only in a bound state. The most common ores are zircon (ZrO2) and barium lead (ZrSiO4).

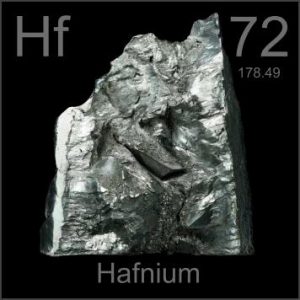

The hafnium (Hf) coexists with zirconium in all its terrestrial ores. The content of hafnium fluctuates greatly, accounting for 2% (the total amount of hafnium and zirconium). The two elements are chemically closer than any other in the periodic table, and the similarities are so great that no difference in mass has been found to separate them.

Zircon

Zircon has been considered a gem since ancient times because it is usually found in large single crystals. However, most commercial deposits of zirconium ore are in beach sand, where the relatively heavy and chemically inert zirconium minerals are retained, while the lighter parts are broken down and washed away by water. India, Malaya, Australia and the United States are known to have large deposits of this sand. Harmful substances have been found in commercially useful deposits, first in Brazil and later in other places, including Sweden, India, and Italy, while some zirconium ores are also commercially mined in Madagascar, Nigeria, Senegal, and South Africa.

Zircon is used as a component of foundry sand, abrasive, and laboratory crucible zircon and zirconia refractories. It is found in ceramic compositions and acts as an emulsifier in glazes and enamels. Zirconium and zirconia bricks are used as glass linings, zirconia templates are also used for extrusion iron and non-ferrous metal molds and injection metal nozzle linings, especially for continuous casting.

Zirconium metal

More than 90% of zirconium is now used in nuclear power generation because zirconium has a low neutron absorption cross-section and is highly resistant to corrosion in atomic reactors, provided it contains no hafnium. In addition, zirconium is used in the manufacture of cast iron, steel, and surgical instruments, as well as in arc lamps, fireworks, special solder, plastic pigments, etc.

The powdered zirconium metal is used as a “getter” in thermionic tubes that absorb traces of residual gas after it has been drained and expelled. The metal, in the form of filaments or wool, is also used as a filter for camera flashes. Block metals can be used in the lining of reaction vessels, either pure or alloyed. It is also used as lining for pumps and piping systems in chemical processes. Excellent zirconium and niobium superconducting alloys are used in the magnetic field of 6.7T.

Zirconium compounds

Zirconium carbide and zirconium diboride are hard, refractory, metallic compounds that have been used in metal cutting tools. Diboride is also used as the shell of open-hearth thermocouples with long life. Zirconium tetrachloride is used in organic synthesis and water repellent in textiles, and it is also useful as a tanning agent.

The metal hafnium has been used as a coating for the tantalum components of rocket engines, which must work at very high temperatures and under corrosive conditions. Because of its high thermal cross-section, it is also used as a control rod material in nuclear reactors. In addition, hafnium is used in the manufacture of electrodes and filament bulbs.

The harm of zirconium

It is not accurate to say that zirconium compounds are physiologically inert, but most organisms seem to tolerate zirconium quite well compared to most heavy metals. Zirconium salts have been used to treat plutonium poisoning to replace the deposition of plutonium (and yttrium) in the skeleton and to prevent precipitation when early processing begins.

Some studies have shown that more than 20% of zirconia can be absorbed in rats for a long time without harmful effects. LD50 of rats injected with sodium zirconium citrate is about 171mg/kg. Other investigators found an intraperitoneal injection of LD50 rats with zirconium lactate 670mg/kg, barium zirconium 420mg/kg, and mice with sodium zirconium lactate 51mg/kg.

Zirconium compounds have been recommended for topical treatment of suede dermatitis and body deodorants, among which are zirconia carbide hydrate, zirconia hydrate, and sodium zirconium lactate. There have been some reports of persistent granulomas on the skin as a result of these applications.

More immediate interest in occupational exposure is the effect of inhaled zirconium compounds, which have not been studied as extensively as other approaches to drug administration. However, there are several experiments and at least one report on human exposure. In this case, a chemical engineer who had been at a zirconium and hafnium processing plant for seven years was found to have granulomatous lung disease. As no similar damage was found on all other employees, it was concluded that the situation was most likely due to relatively high levels of beryllium prior to zirconium contact.

Animal exposure to zirconium compounds has shown that severe persistent chronic interstitial pneumonia occurs in both zirconium lactate and barium zirconium at atmospheric concentrations of about 5mg/m3. Short exposure to sodium zirconium lactate at a higher air concentration of 4900mg/m3 resulted in peribronchoabscess, peribronchogranuloma, and lobular pneumonia. Despite the lack of literature on human zirconia pneumoconiosis, the authors of one study suggest that zirconium should be considered as a possible cause of pneumoconiosis and recommend appropriate precautions in the workplace.

A small number of studies on the toxicity of hafnium compounds indicate that their acute toxicity is slightly higher than that of zirconium salts. Like soluble zirconium salts, hafnium chloride-induced cardiovascular failure and respiratory arrest in cats at 10mg/kg.

Safety and health measures

- Zirconium is burned as a fine powder in air, nitrogen or carbon dioxide. The spontaneous air explosion of these powders at concentrations of 45,000 to 300,000 mg/m3 may be caused by static electricity generated by the separation of the disturbed particles.

- Metal powders should be transported and treated in a wet state; water is usually used for wetting. When the powder is dried before use, the amount used should be as small as possible and should be operated in a separate compartment to prevent the spread of the explosion.

- All ignition sources including electrostatic charges should be eliminated. All surfaces in the area should be impermeable and seamless so that they can be washed down with water and completely free from dust. Any spilled powder should be washed with water immediately so that it has no chance to dry. Old paper and cloth contaminated with powder should be kept moist in a covered container until they are removed and burned, at least daily.

- Dry powders should be treated with as little interference as possible, and then only sparkless tools should be used. Rubber or plastic aprons, if worn on overalls, should be treated with antistatic compounds. Work clothes shall be made of non-synthetic fibers unless effectively treated with antistatic materials.

- All processes using zirconium and hafnium should be designed and ventilated to keep air pollution below exposure limits.

Stanford Advanced Materials supplies high-quality zirconium products to meet our customers’ R&D and production needs. Please visit https://www.samaterials.com/ for more information.