Zircons are highly resistant to high temperatures and acid corrosion, and their melting can reach 2,750℃. 80% of the world’s zircons are used directly in the foundry, ceramics, glass, and refractory industries, while a small amount is used in ferroalloys, pharmaceuticals, paint, leather, abrasive, chemical, and nuclear industries. The main industrial uses of zircon are as follows.

Zircon sand

Zircon sand containing ZrO2 65~66% is directly used as casting material for the iron metal in foundry due to its melting resistance (melting point above 2500℃). Zircon sand has a lower thermal expansion, higher thermal conductivity, and stronger chemical stability than other common refractory materials, and high-quality zircon and other adhesives have a good bond and are used in the foundry industry. Zircon sand is also used as bricks in glass kilns. Zircon sand and powder are mixed with other refractory materials for other purposes.

Zirconium oxide

Zirconium and dolomite react together at high temperatures to produce zirconia or zirconium oxide (ZrO2). Zirconium oxide is also a good melting material, although its crystal shape varies with temperature. Stable zirconium oxide also contains small amounts of oxides of magnesium, calcium, scandium, or yttrium. The stable melting point of zirconium oxide is close to 2700℃, and it is more resistant to thermal shock than zirconium in some metallurgical applications. Stable zirconium oxide has low thermal conductivity, and the use of hafnium dioxide as fusible in industrial zirconium oxide is harmless.

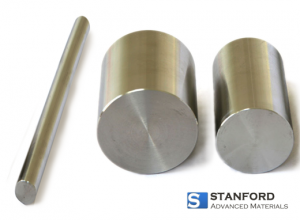

Zirconium metal

Zirconium metal is mainly used in the chemical and nuclear reactor industries, as well as in other industries requiring corrosion resistance, high-temperature resistance, special fusion properties or special neutron absorption. In the United States, about 8% of the total consumption of zirconium metal is used in these industries, while the only meaningful application of the hafnium metal is in the nuclear reactors of warships.

Zirconium metal is obtained by multistage extraction. Initially, zircon reacts with coke in an electric furnace to produce zirconium hydrocarbons and then chlorinates to produce zirconium tetrachloride. The magnesium reduction of the zirconium tetrachloride process involves the reduction of tetrachloride by placing magnesium metal in an inert gas to obtain spongy zirconium.

High purity zirconium metal can be refined by iodide thermal dissociation. In this process, metal and iodine vapors react at 200℃ and send volatile iodine to the connector, separating zirconium in the form of volatile iodine from most impurities. At about 1300℃, iodide is separated on a heated filament attached to highly purified zirconium. The released iodine is transferred from the filament, and the product is called a zirconium crystal rod.

Zirconium sponge

More than 90% of zirconium sponge is used as a zirconium-based alloy for structural and cladding materials in nuclear reactors. Zirconium is used in the chemical industry, pesticide industry, printing, and dyeing industry to manufacture corrosion-resistant reaction towers, pumps, heat exchangers, valves, stirrers, nozzles, pipes, and container lining. It can also be used as a deoxidizing and denitrifying agent in the process of steelmaking and grain finisher of aluminum alloy. Zirconium wire can be used as grid support, cathode support and grid material, as well as air plasma cutting machine electrode head. Zirconium powder is mainly used as a deflagrant in the arms industry, a degassing agent in electronic devices, and it can also be used to make igniters, fireworks and flash powder.

Stanford Advanced Materials supplies high-quality zirconium products to meet our customers’ R&D and production needs. Please visit https://www.samaterials.com for more information.