With the gradual improvement of people’s awareness of environmental protection and energy conservation, many large and medium-sized enterprises, such as iron and steel metallurgy, petrochemical industry, thermal power plants, etc., have taken improving combustion efficiency, reduced energy consumption, reduced pollutant emissions, protecting the environment as an important way to improve product quality and enhance enterprise competitiveness.

Generally speaking, the direct way to improve the combustion efficiency is to continuously monitor the composition of flue gas in the flue gas analysis instrument (such as a flue gas analyzer, combustion efficiency tester, zirconia oxygen content detector), then analyze O2 content and CO content in flue gas, adjust the flow rate of combustion air and fuel, and determine better air consumption coefficient. Therefore, as an industrial tool to improve combustion efficiency, the oxygen sensors’ response time and measurement accuracy become key performance indicators. Due to its simple structure, short response time, wide measurement range (from PPM to percentage), high operating temperature (600℃-1200℃) and small maintenance, zirconia oxygen sensor has been widely used in metallurgy, chemical industry, electric power, automobile, and other fields.

Principle of zirconia sensor

The figure below is the schematic diagram of oxygen measurement with an oxygen probe. Porous platinum (Pt) electrodes were sintered on the two sides of the zirconia electrolyte (usually a zirconia tube). At a certain temperature, when the oxygen concentration on both sides of the electrolyte is different, the oxygen molecules on the high concentration side (air) are adsorbed on the platinum electrode and combine with electrons to form oxygen ions, making the electrode positively charged. The oxygen ions then migrate through the oxygen ion vacancy in the electrolyte to the Pt electrode on the low oxygen concentration side, releasing electrons and transforming them into oxygen molecules, making the electrode negatively charged.

This creates a certain electromotive force between the two electrodes. The zirconia electrolyte, the platinum electrode, and the gas with different oxygen concentrations on both sides constitute the oxygen probe, which is called the zirconia concentration difference cell. Then, by measuring the gas temperature and the output electromotive force, the oxygen partial pressure (concentration) can be calculated by the nengest equation, which is the basic detection principle of the zirconia oxygen sensor.

Common types of zirconia oxygen sensors

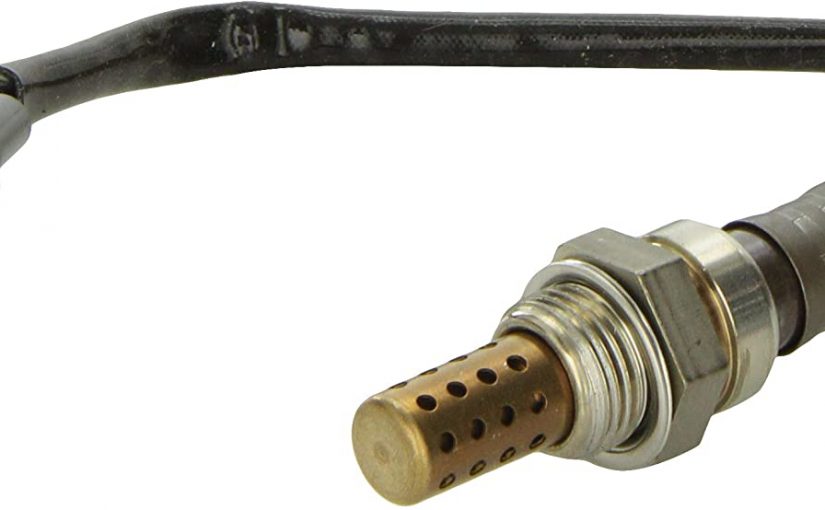

At present, the commonly used zirconia oxygen sensor includes a detection probe and direct insertion oxygen probe.

Detector probe

The sampling method is to introduce the measured gas into zirconia through a guide tube and then heat the zirconia to the working temperature (above 750℃) through a heating element. Zirconia is typically tubular and the electrode is porous platinum. Its advantage is that it is not affected by the temperature of the gas detected, and the oxygen content of the gas can be detected by using different flow guides at different temperatures.

This flexibility is used in much industrial on-line detection. Its disadvantages are slow response; the structure is complex and easy to affect the detection accuracy; when there are many impurities in the measured gas, the sampling tube is easy to be blocked; the porous platinum electrode is easy to be corroded by sulfur and arsenic or blocked by fine dust, etc. When the temperature of the detected gas is low (0-650℃), or when the measured gas is clean, it is suitable to use this detection method, such as oxygen measurement by nitrogen production machine and laboratory.

Direct probe

The direct insertion method is to directly insert zirconia into the gas measured at high temperature and directly detect the oxygen content in the gas. It uses the high temperature of the measured gas to bring zirconia to its operating temperature without the need for additional heaters.

The key technology of the direct insertion oxygen probe is the high-temperature sealing of ceramic material and the electrode. Due to the need to insert zirconia directly into the detection gas, the length of the oxygen probe is required to be relatively high. The effective length is about 500mm ~ 1000mm, and the special environment length is up to 1500mm, as well as high requirements for detection accuracy, working stability and service life. Therefore, it is difficult to adopt the whole zirconia tubular structure of the traditional zirconia oxygen probe with a direct insert oxygen probe, and the zirconia and alumina tube connection structure with high technical requirements is mostly adopted. The sealing performance is one of the most important technologies for the zirconia oxygen probe. Currently, the most advanced connection mode in the world is the permanent welding of zirconia and alumina tubes together.

Compared with the method of sampling pattern detection, the direct insertion method has obvious advantages: zirconia directly contacts with gas; high detection accuracy; fast reaction speed and small maintenance.

Brief summary

The regulation of oxygen content is a powerful means to monitor combustion conditions and improve combustion efficiency, and the accuracy and time of the measurement of the sensor have put forward certain requirements. Zirconia, as a solid electrolyte, is used to transport conductive ions in oxygen sensors. At present, there are two kinds of zirconia oxygen sensors: detection type and direct insertion type. The direct insertion type probes are widely used because of their direct contact with the measured gas, high measurement accuracy and fast reaction time.

Stanford Advanced Materials supplies high-quality zirconia products to meet our customers’ R&D and production needs. Please visit https://www.samaterials.com/ for more information.