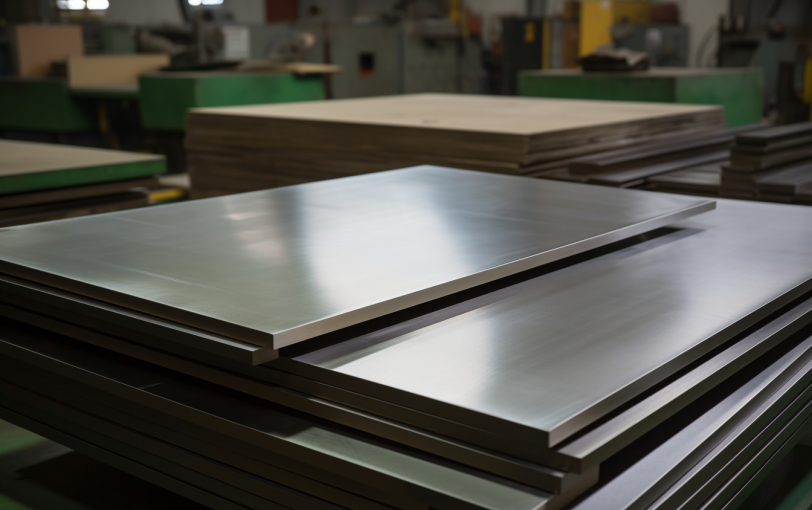

Zirconium sheet is a valuable material known for its exceptional corrosion resistance and heat transfer properties. However, working with zirconium requires careful handling and adherence to specific guidelines to ensure safety and maintain the material’s desirable properties. This article outlines best practices for handling, cutting, welding, and fabricating zirconium sheet, providing insights into proper storage, equipment selection, and safety precautions.

Further Reading: An Introduction to Zirconium Sheet: Properties and Applications

Storage and Handling

Proper storage of zirconium sheet is crucial to prevent contamination and damage. Store sheets in a clean, dry area away from direct sunlight, moisture, and corrosive substances. Use pallets or racks to prevent contact with the floor and keep sheets separated to avoid scratching or deformation. When handling zirconium sheets, wear gloves to prevent fingerprints, which can affect the material’s surface and subsequent fabrication processes.

Equipment Selection

When working with zirconium sheet, it’s important to use appropriate tools and equipment to prevent contamination and ensure precise fabrication. Select cutting tools, saw blades, and grinding wheels specifically designed for zirconium or other reactive metals. Avoid using carbon steel or iron-based tools that can contaminate the surface and compromise the corrosion resistance of the zirconium sheet.

Cutting and Machining

Zirconium sheet can be cut using shears, band saws, or abrasive waterjets. For precision cutting, using waterjets or laser cutting is recommended. When machining zirconium, ensure proper cooling with water-based lubricants to dissipate heat and prevent overheating. Maintain low cutting speeds to minimize heat generation and avoid work hardening, which can lead to cracking or reduced ductility.

Welding and Joining

Zirconium sheet can be successfully welded using various techniques such as TIG (Tungsten Inert Gas) welding or electron beam welding. Before welding, ensure the sheet and welding area are clean and free from contaminants. Use specialized zirconium welding filler rods with matching composition to maintain the material’s corrosion resistance. Strictly follow proper shielding gas techniques to prevent oxygen and nitrogen contamination during welding.

Safety Precautions

Working with zirconium sheet requires strict adherence to safety precautions due to its reactive nature. Wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and protective clothing. Implement proper ventilation in the workspace to control dust and fumes. Avoid contact between zirconium and flammable materials, as it can ignite under certain conditions. In case of a fire involving zirconium, use dry powder or sand to extinguish it, as water can react explosively with zirconium at high temperatures.

Surface Finishing

Zirconium sheet surfaces can be enhanced through various finishing techniques like polishing, brushing, or electrochemical etching. However, it is essential to avoid contact with abrasive cleaning pads or brushes that can introduce contamination. Utilize specialized tools and cleaning agents specifically designed for zirconium to maintain its integrity and surface quality.

Quality Control

Implement stringent quality control measures throughout the handling and fabrication process to ensure the integrity of zirconium sheet. Conduct regular inspections to identify any signs of contamination, damage, or defects. Non-destructive testing methods such as dye penetrant testing or ultrasonic testing can be employed to detect surface cracks or flaws that may compromise the material’s performance.

Conclusion

Following best practices for handling and fabricating zirconium sheet is paramount to ensure safety and maintain its desirable properties. Proper storage, equipment selection, and adherence to safety precautions while cutting, welding, and finishing zirconium sheet are crucial. By following these guidelines, industries can maximize the benefits of zirconium sheet, including its exceptional corrosion resistance, heat transfer efficiency, and mechanical properties. Remember, when in doubt, consult with material suppliers or experts experienced in working with zirconium to ensure the highest standards of safety and quality.

For more information about zirconium sheets and other zirconium products, please visit https://www.samaterials.com/70-zirconium.html.