Zirconia is a new structural ceramic material developed in the 1970s. It is widely used in metallurgy, electronics, chemical industry, machinery and other fields due to its abrasion resistance, corrosion resistance, high strength, and high melting point.

Zirconia ceramic material, the most important material in advanced ceramics, is an important basic material for the development of the modern high-tech industry. In particular, nano-oxide ceramics with their special structure and performance has become the focus of the industry. The following is a brief introduction to the powder materials needed to prepare nano zirconia ceramics.

Ni-P coated nano zirconia composite powders

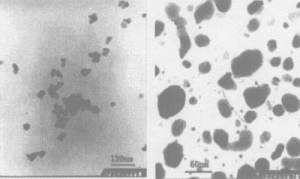

The preparation process of Ni-P coated nano zirconia (ZrO2) composite powders is firstly to prepare nano-ZrO2 powders by the chemical precipitation method, and then to prepare Ni-P nano-ZrO2 powders by an electroless plating method. Since ZrO2 has no autocatalytic activity in the electroless nickel plating solution, it is necessary to pretreat ZrO2 nanoparticles. Generally, Pd2+ is directly adsorbed on the surface of ZrO2 powder by the one-step palladium catalysis method, and then Pd2+ is reduced to palladium in a reducing solution so that the surface of nanopowder has the catalytic activity of electroless nickel plating. The two-step sensitization-activation method is usually used in the pretreatment of non – conductive powders. However, it is difficult to remove the residual nickel ions in the powder after two-step treatment, which often brings adverse effects on the activity of the powder. At present, one-step palladium catalysis and in-situ palladium pretreatment are used.

At present, Ni-P coated nano zirconia composite powders have been widely used and studied in semiconductor nanomaterials.

Zirconia toughened alumina ceramic composite powder

Zirconia toughened alumina ceramic is one of the most widely studied structural ceramic materials. The toughening mechanism of zirconia toughening alumina ceramics is the refinement of matrix grain, the toughening of phase change, the toughening of microcrack, and the turning and bifurcation of crack. The properties of zirconia toughened alumina ceramics are mainly determined by the microstructure formed during sintering, and the microstructure is mainly determined by the powder state of raw materials. Therefore, the preparation of high-quality Al2O3/ZrO2 nanocomposite ceramic powders is the prerequisite for the preparation of zirconia toughened alumina ceramics with excellent properties. The preparation methods of Al2O3/ZrO2 nanocomposite ceramic powders mainly include the mechanical mixing method, multi-phase suspension mixing method, the sol-gel method, chemical precipitation method, etc.

Alumina is a kind of high-strength matrix in the composite ceramic system of zirconia toughening alumina, and the zirconia in the intercalation provides a phase change toughening mechanism. The use of ZrO2 phase change properties to toughen ceramic materials is still one of the main research topics of ceramic toughening in the future.

Zirconia toughened alumina composite ceramics have excellent corrosion resistance, thermal shock resistance, high strength, and toughness, as well as wide application prospects. Zirconia toughened alumina composite ceramics can be used to make ceramic cutters for the processing of cast iron and alloy, and the interface structure of engineering ceramics can be made to extend the service life of engineering materials. Alumina toughened with zirconia can be used to make wear-resistant ceramic balls. Due to its good biocompatibility, alumina can also be used as a biomedical material for the reconstruction and repair of hard tissues (teeth).

Boron nitride-zirconia composite powder

Boron nitride-zirconia composite powders were prepared by mechanical mixing method. Boron nitride, zirconia, and additives were used as the main raw materials. After mixing, the powders were ball-ground and mixed in an alcohol medium, and then the zirconia composite ceramics were sintered in a hot press sintering furnace. Due to the poor sintering capacity of pure boron nitride and its difficulty in sintering densification, CaO, B2O3, Al2O3, and ZnO are generally added as sintering AIDS.

Boron nitride-zirconia composite ceramics are characterized by high strength, high toughness, high thermal conductivity, low expansion, and excellent physical and chemical properties, such as chemical inertness and chemical corrosion, which are present in molten metals. In addition, it also has excellent thermal shock resistance, erosion resistance, wear-resistance and easy processing and other properties, which make the material suitable for thin strip continuous casting side seal plate, jet forming liquid guide pipe, the nozzle for metal spinneret, continuous casting functional refractories and other fields.

Nano cerium-zirconium composite oxide powder

The preparation methods of nano cerium-zirconium composite oxide powders include high-temperature roasting, the sol-gel method, coprecipitation method, hydrothermal method, and solid-phase reaction method. High-temperature roasting was carried out in a water-ethanol solvent, and the suspension consisted of dry Al (NO3) 3•9H2 O•Ce (NO3) 3•6H2O and monocline phase zirconia nano-powder was pyrolyzed by high-temperature, Al2O3 doped CeO2 coated monoclinal zirconia powders with a particle size less than 100 m were prepared.

Nano cerium-zirconium composite oxide materials are used as auxiliary catalysts, mainly used in automobile exhaust treatment, with good high-temperature stability, high REDOX ability, high oxygen storage, and release capacity.

Please visit http://www.samaterials.com for more information.